Comparison With Other Materials

SAGAR uPVC riser/drop/column pipes are perfect replacement to conventional Galvanized Iron pipes used in bore wells and hold several critical advantages over conventional Mild steel or Galvanized steel pipes, which are

| Property Requirement for Drop/Riser/Column Pipes |

SAGAR uPVC COLUMN Pipes |

Mild Steel or Galvanized Steel Pipes |

| Long life |

SAGAR uPVC Column pipes do not react with acidic or alkaline water and have a long life in the bore wells. |

Steel pipes are prone to rust, corrosion & ultimately get damaged and need to be replaced quickly. |

| Light weight |

Pipes are Light in weight and are easy to handle, install and remove. |

Pipes are heavy and a great effort is required for installation or maintenance. Difficult to handle. |

| Smooth Internal Surface |

Internal surface is smooth. Therefore low head loss due to friction & results in higher discharge of water. |

Rough internal surface and head loss is high resulting in less discharge of water. |

| Leak proof joints |

Rubber seals are provided with the thread at every joint ensuring 100% leak proof. |

Not pressure tight, No rubber seal & hence NOT Leak proof. |

| Strong threaded joints |

Specially designed square Threads, which DO NOT corrode, rust or deteriorate. |

Threads are prone to rust and corrosion easily. |

Why PVC For Column Pipes ?

For many years, Metal pipes have been used with submersible pumps to get the water from ground. These pipes are corrode and scaled in their life span and giving troubles to the owner in terms of qty of water and also the pumping cost. PVC has excellent chemical and corrosion resistance to a broad range of fluids. So PVC can give trouble free service for many years.

Secondly, among all thermoplastics also, PVC is the material which can be compounded and modify keeping in the mind of special characteristics required for pipes to be used with submersible pumps. This versatility is not observed with other thermoplastics like Polyethylene (PE). Hence PVC contributes to major usage as piping material globally.

Why SAGAR Column Pipes ?

SAGAR column pipes have been developed as a result of SAGAR's constant endeavor to develop superior yet economical piping solution for submersible pumps. The compound has been developed at SAGAR's R & D lab after many trials and constant research with the help of German technology. SAGAR's expertise in introducing better compound in Indian Market, comes true yet another time with introducing completely Eco Friendly column pipes

The raw material such developed is processed in state of the art machines which contribute to highest pipe quality with most accurate dimensions. Then Pipes will be threaded in very high accuracy which are very essential for performance of column pipes. The thread geometry is such designed that it will give highest strength against vertical column load as well as pressure developed due to pump operation.

Unique Features

Special Compound

SAGAR Column pipes are manufactured from Special uPVC compound material especially developed by using “JAPANESE TECHNOLOGY” to sustain best column loads, pressure and also encounters the high impact developed during handling, storage and installation. Due to this special compound the TENSILE property of pipe increase which is being tested rigorously using modern testing equipment.

Locking System

SAGAR pipes and couplers are joined with special joining compound which makes lifetime permanent joint without affecting the thread dimensional stability in longer service life.

Bi - Aaial Orientation On Pipes

Every pipe is being oriented biaxially during manufacturing which is a very special technique developed by SAGAR. This will really enhanced the mechanical properties of pipes which make sure that the pipes will perform best during application.

100% Hygienic / Safe For Drinking Water

Supply of drinking water is 100% hygienic and safe as being pumped through SAGAR uPVC column pipes manufactured from special METAL FREE compound right from the origin of water source beneath under the earth at maximum depth.

Salient Features

Square Threads:

Unique square threads made with high accaracy provide sufficient grip and additional strength against tensile load. Thus the joint become fairly strong with sufficient factor of safety to take care of load of entire assembly with pump weight. These specially designed threads also make it suitable for easyfitment.

Thin And Thick Process:

The pipe ends are specially given the effect of additional wall thickness by using Thin & Thick process to compensate the strength and load bearing capacity caused due to threading of pipes. The effect of Thin & Thick is given to all sizes considering the working conditions & load factor.

'O' Ring

Specially designed "O" rings provided on the threads makes the joints watertight and absorb pump vibrations.

Step Ring:

for locking of pipe with coupler specially designed working properly because of bearing jam and shaft problem it makes vibration. At that time stepring absorbs makes vibration and stop in damaging the system. So step ring work for both locking and vibration absorber.

Column Pipe Key Properties

- Manufactured from high quality virgin PVC compound, also reliable for drinking water.

- Chemical and corrosion resistance

- Long life

- Smooth inner wall, no scale build up.

- Low friction loss, resulting in energy saving, efficient pumping.

- 100% leak proof joint with rubber '0' rings and step ring.

- Light in weight, easy to transport.

- Fast and easy installation.

- Low installation cost. Does not require wrenches, threading tools or solvent cement.

- No curing period, immediate pump testing possible.

- High impact resistance.

Field Of Applications

Water rising for submersible pump, domestic and industrial applications. Ideally suitable for long term use in salty, sandy and chemically aggressive water.

Column Pipe Sizes

Available Size:

- 1 "-V4 (12.5 kg/cm2), Medium and Standard

- 114", 11h'' -V4(12.5kg/cm2), Medium, Standard and Heavy

- 2", 21h'', 3", 4", 5"& 6" Heavy(inStandard & LongCoupler)

- 2", 21h", 3", 4", 5"SuperHeavy

Shortly Introducing:

- 2"-V4(8kg/cm2)

- 6" - Super Heavy

uPVC Column pipes Installation Procedures

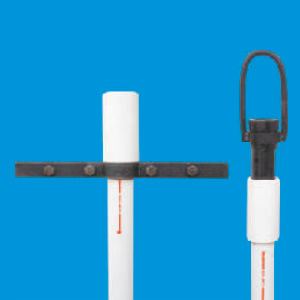

SAGAR® Strong n Safe™ Fit the Clamp Installation Guide:

To Lower Column Pipe, fit the clamp under the threads

Fix The Adaptor

Fix the Adaptor to Pump with wrench support, tightly.

Wash With Clean Water

Wash PVC male and female Threads with plain water before use.

Install Pump Guard

Install pump guard with help of two flanges & two rods & small piece of PVC pipe and coupler with adaptor properly

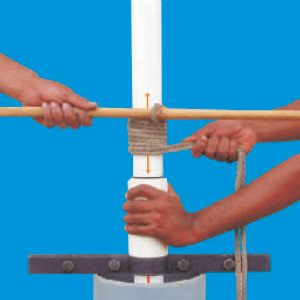

Insert Pipes

Hold down the coupler firmly with hand while joining and tighten the pipe with hand or rope upto half level of rubber ring

Fixing & lovering of pipes

Tighten the pipes with last jerk and then lover the pipe with the help of lovering jig I clamp by chain pulley

Handling And Storage

Handling

The pipe should be handled with reasonable care. Because Column Pipes are much lighter in weight than metal pipe. There is sometimes a tendency to throw it around. This should be avoided.

The pipe should never be dragged or pushed from a truck bed. Pallets for pipe should be removed with a fork lift. Loose pipe can be rolled down timbers, as long as the pieces do not fall on each other or on any hard or uneven surface. In all cases, severe contact with any sharp objects (rocks, angle irons, forks on forklifts, etc.) should be avoided.

Storage

If possible, pipe should be stored inside. When this is not possible, the pipe should be stored on level ground which is dry and free from sharp objects. If different schedules of pipes are stacked together, the pipe with the thickest walls should be at the bottom.

The pipe should be protected from the sun and be in an area with proper ventilation. This will lessen the effects of ultraviolet rays and help prevent heat built-up.

If the pipe is stored in racks, it should be continuously supported along its length. If this is not possible, the spacing of the supports should not exceed three feet (3’).

When storage temperatures are below 0°C (32°F), extra care should be taken when handling the pipe. This will help prevent any problems which could be caused by the slightly lower impact strength of uPVC pipe at temperature below freezing.

Read Less