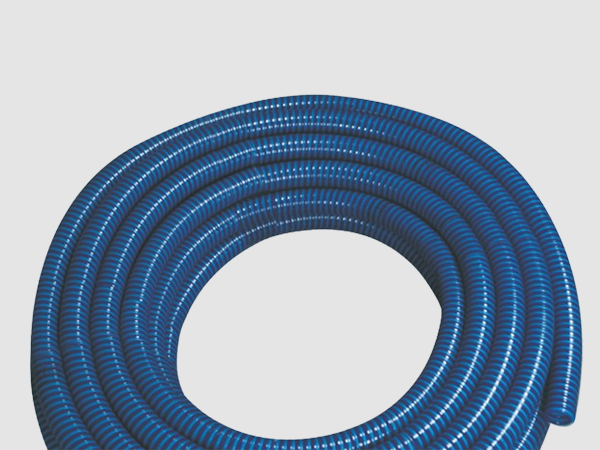

Sagar Flex'O'Flex PVC Oil Hose is highly specialized product made from special polymer compound that provides resistance to oil and other light petroleum products. Unlike rubber hose, Sagar Flex'O'Flex PVC oil Hose will neither be cracked nor aged hence our oil hoses are durable for very long period and thus proves economical.Sagar Flex'O'Flex PVC oil hoses are made by adequate reinforcement secured by proper placement of hard spirals of rigid thermoplastic material like PVC in soft PVC wall that imparts strength and flexibility.

Applications:

- Suction & Discharge of oil.

- Various application in liquid petroleum product.

- Transportation of lubricating oil, mineral oils, light oils, Transformer oils etc.