Sagar Strong'N'Safe CPVC plumbing system is designed for hot and cold water supply in residential, commercial and public projects, high and low rise buildings, corporate houses and academic institutes, solar heater applications, etc. It is suitable for all uptakes and down take lines, terrace looping, and concealed pipe work applications. The choice of the raw material, the structural accuracy, and the strict quality control impart a high degree of reliability to Sagar Strong'N'Safe CPVC. Sagar Strong'N'Safe is the most suitable, easy, and economic solution for the transportation and distribution of potable water. It is technically much superior, cost-effective, and offers many advantages over GI and other conventional systems.

Applications:

- Building Construction.

- Sanitary Application.

- Portable Water Supply.

- Industrial Application.

Note:

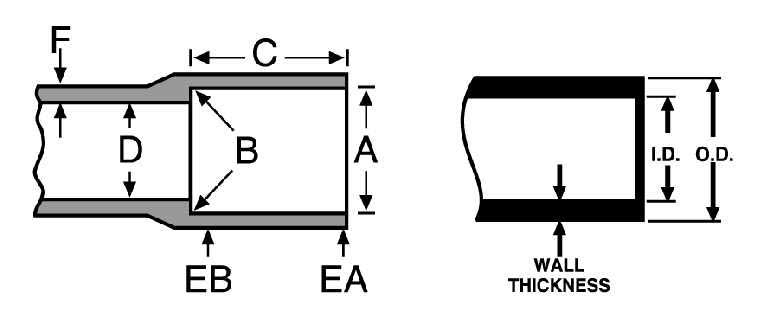

- Non Standard wall thickness, length and color can also be offered If desired.

- Pipes can also be offered as per DIN 8062, ISO 4422-2, BS 3505/6.

For HOT & COLD Water Application

Corrosion resistance:

SAGAR CPVC Pipe gives excellent resistance even under the harshest of water conditions so there are none of the purity worries from corrosion of metal pipe or soldered joints. SAGAR CPVC Pipe keeps pure water pure.

Lower bacterial growth:

Bacteria build up with CPVC is far lower than with alternative piping materials - Copper, Steel and other thermoplastics.

No Scale, pit or leach formation:

Even after years of use in the most aggressive conditions, SAGAR CPVC pipe won’t corrode, standing up to low pH water, coastal salt air exposures and corrosive soils. SAGAR CPVC Pipe stays as solid and reliable as the day it was installed. It maintains full water carrying Capacity because its scale resistance means no build up to cause water pressure loss.

Unaffected by chlorine in the water

Some materials may be adversely affected by chlorine contained in the water supply, which can cause breakdown of the polymer chains and potential leaks. In this respect, SAGAR CPVC pipe is unaffected by the chlorine present in potable water supply.

Low thermal expansion:

SAGAR CPVC pipe has a lower coefficient of thermal expansion than alternative plastics, reducing the amount that the pipe expands when hot water is running, again reducing unsightly ‘looping’ of the pipe.

Easy Plumbing process:

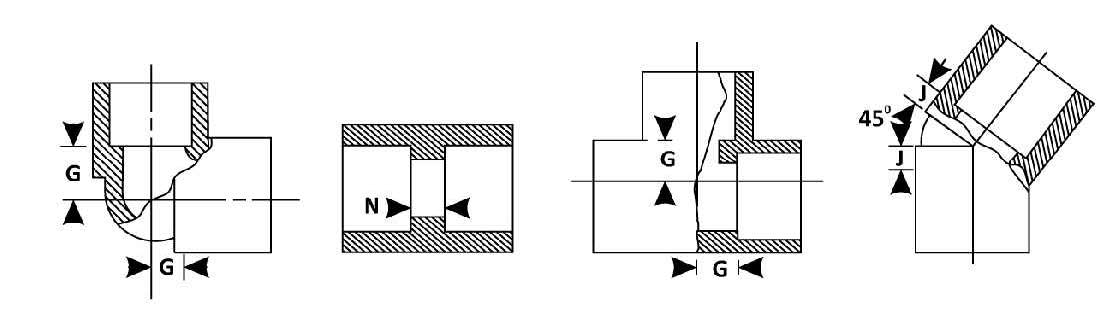

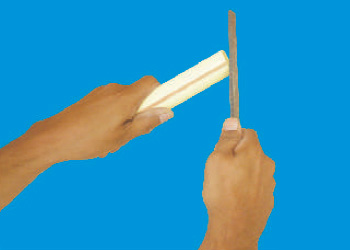

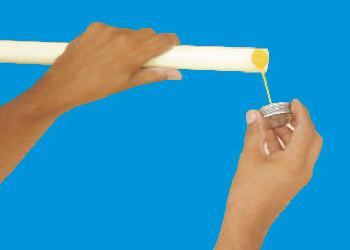

CPVC uses a simple, solvent cement jointing method. Tools required are very simple and inexpensive (chamfering tool and pipe cutter only) and avoid the need for an electrical source. Superior insulation : SAGAR CPVC pipe is more energy efficient than metal pipe. As an insulator it does not lose heat the way metal pipe do. Heat loss and thermal expansion are reduced. Superior insulation:

Hot water compatible:

SAGAR CPVC pipe is compatible with both hot and cold water. It withstand very high temperature compared to any other thermoplastic plumbing systems. Many solar and electric water heaters have CPVC piping system for heat efficiency and lower installation cost.

Tough, rigid material:

SAGAR CPVC pipe has a much higher strength than other thermoplastics used in plumbing. This means that CPVC needs less hangers and supports and there is no unsightly looping of the pipe. SAGAR CPVC pipe Has a higher pressure bearing capability. This leads to the same flow rate with a smaller pipe size.

Fire safety:

CPVC has a limiting Oxygen Index (LOI) of 60. Thus in air, SAGAR CPVC pipe does not support combustion. No flaming drips, does not increase the fire load, low flame spread, low smoke generation.

Approved world wide:

CPVC plumbing system is approved for contact with potable water in wide range of countries including USA, UK, Canada, Germany, France, The Netherlands, Middle East among others. Here in India, SAGAR CPVC plumbing system is approved by BMC and CPWD for potable water supply.