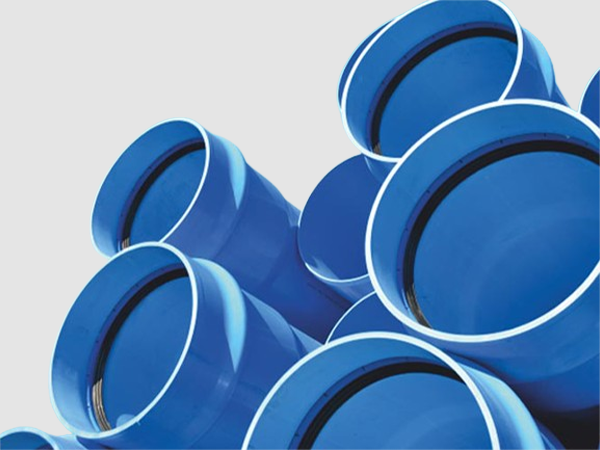

Sagar Hulk PVC-O pipes are a product developed exclusively with the innovative technology that provides the highest Molecular Orientation. The manufacturing process is continuous and completely automatic, which ensures the maximum product reliability and a quality control tube to tube for the 100% of the production. It is the best solution for the conveyance of water at medium and high pressure for irrigation systems, drinking water supply, reuse, industrial or fire protection lines, among other uses. Sagar Hulk PVC-O pipes is the best alternative to Ductile Iron pipes and any other high pressure supply main line.

HULK PVC – O pipes are suitable for the following application:

- Potable water supply.

- Conduits for the conveyance of potable water. It includes water adduction, water supply networks to city centers and industrial areas, and water impulsion transfers to tanks and reservoirs.

- Reclaimed water.

- Conductions for the transport of water that has been treated to remove impurities.

- Irrigation.

- Conductions for the conveyance of water for irrigation purposes. It includes both pipelines to irrigated areas and distribution to plots, as well as impulsions to tanks.

Other applications:

- Sewage

- Fire protection networks

- Industrial applications

- Infrastructural nets