Sagar Strong'N'Safe Composite Pipes has been selected to meet compressive and flexural strength requirements. This helps to combine the advantages of metal and plastic pipes and eliminate the disadvantages of both materials at the same time. The aluminium core is absolutely diffusion tight and reliably prevents oxygen or gases from permeating into the pipe. It compensates and reduces snap-back forces and heat expansion with changes in temperature.

Applications:

As a key type of Building Material, it is widely used in the following fields:

- Polygon PEX under-floor heating system.

- Polygon PEX Plumbing system.

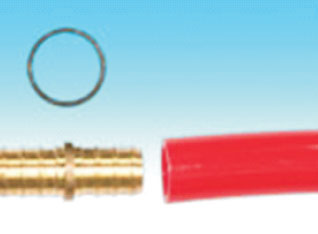

- Easy installation and sufficient accessories

The PEX pipe acquires easy installation and sufficient accessories due to the flexibility, less but special pipe fittings. Even without tap threading, die threading or welding, it can be matched with the standard pipe fitting. - Advanced technology and imported materials

With advanced equipment from NOKIA-MAILLEFER and international patent USP4117195, one-step Monosil PEX producing technology, we used imported materials which are compliant to the GB!T18992.2 standard to ensure the high performance of the pipe. Steam-pressure cross-linking technology is used to reduce the longitudinal shrinkage. - Satisfying customers' requests

According to the customers' requests, we offer oxygen-leaking resistant layer and anti-UV composite PE-Xb pipe. We also promise fast production of 20m/min (ON 20mm pipe), quick delivery and production with customized size.