SAGAR® uPVC SWR Ringfit Systems Technical Specifications:

| Inside Dia of Socket |

Length of

Beading & Neck |

Length Beyond

Beading |

| Min |

Max |

Min |

Min |

| 75.30 |

75.60 |

20.00 |

25.00 |

| 75.30 |

75.60 |

20.00 |

25.00 |

| 90.30 |

90.20 |

23.00 |

28.00 |

| 90.30 |

90.20 |

23.00 |

28.00 |

| 110.40 |

110.30 |

26.00 |

32.00 |

| 110.40 |

110.30 |

26.00 |

32.00 |

| 160.50 |

160.50 |

32.00 |

42.00 |

| 160.50 |

160.50 |

32.00 |

42.00 |

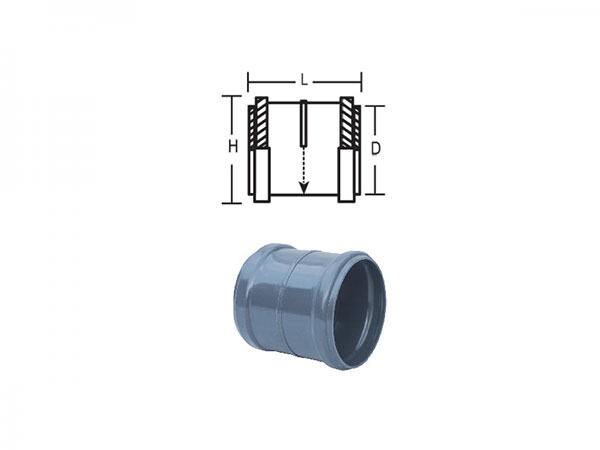

Selfit Socket

SAGAR® uPVC SWR Selffit Socket Systems Technical Specifications:

Socket Depth

min |

Mean ID Socket at Mid Point |

| |

Min |

Max |

| 40 |

75.10 |

75.30 |

| 40 |

75.10 |

75.30 |

| 46 |

90.10 |

90.30 |

| 46 |

90.10 |

90.30 |

| 48 |

110.10 |

110.40 |

| 48 |

110.10 |

110.40 |

| 58 |

160.20 |

160.50 |

| 58 |

160.20 |

160.50 |

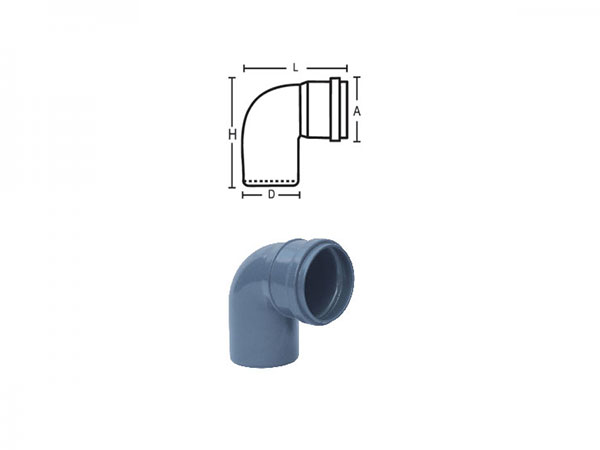

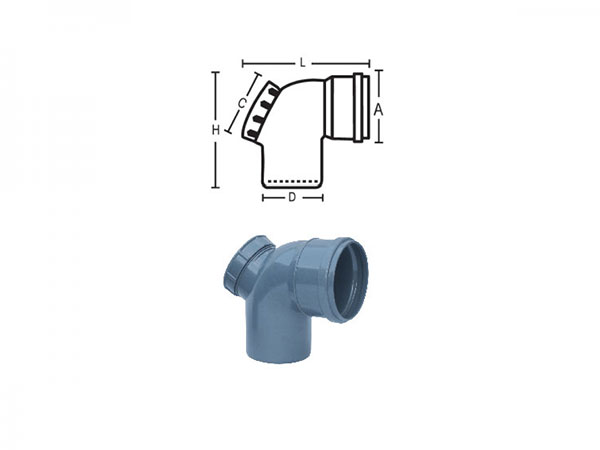

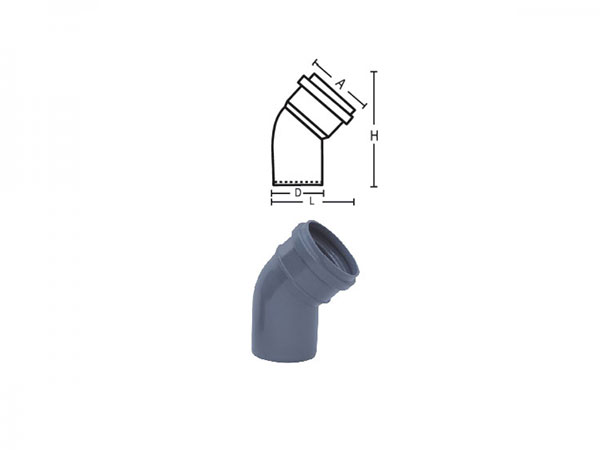

Technical Specification of Fittings as per IS: 14735

| Size (mm) |

Wall Thickness at Plain End (mm) (min) |

Wall Thickness at Socket (mm) (min) |

Socket Depth (mm) (min) |

Inside Diameter of Socket at Mid Point (mm) |

Outside Diameter of Spigot Portion (mm) |

| Min |

Max |

Min |

Max |

| 75 |

3.20 |

2.90 |

40.00 |

75.10 |

75.30 |

75.00 |

75.30 |

| 90 |

3.20 |

2.90 |

46.00 |

90.10 |

90.30 |

90.00 |

90.30 |

| 110 |

3.20 |

2.90 |

48.00 |

110.10 |

110.40 |

110.00 |

110.40 |

SAGAR SWR System

SAGAR SWR systems includes following:

uPVC SWR Pipes

SAGAR uPVC SWR pipes are as per IS: 13592 specifications. They are available in type A and type B. They are also classified with the types of pipe end.

One end is plain and the other end has either sliding socket or grooved socket. Sliding socket end pipes can be joint with solvent cement forming a

permanent water tight joint and recommended for horizontal lines as these lines are mostly buried in the flooring while grooved socket end pipes can be

joint with rubber ring forming a detachable water tight joint which allows thermal expansion and contraction.

Advantages Of Rubber Ring Joint

- It can be opened and closed as per requirement means it is flexible joint.

- It permits axial contraction and expansion and also angular deflection.

- Using of pipelines is immediate after laying without any curing time.

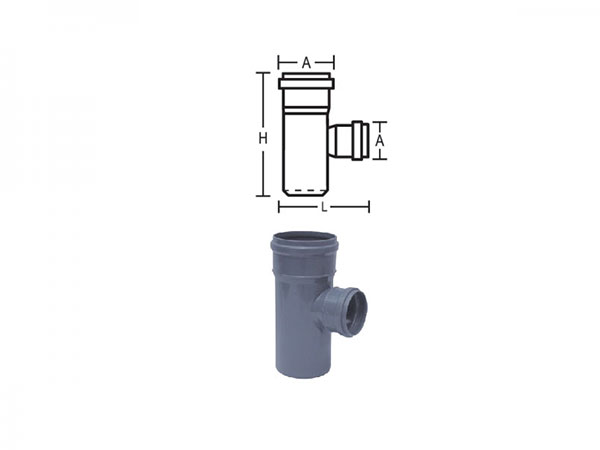

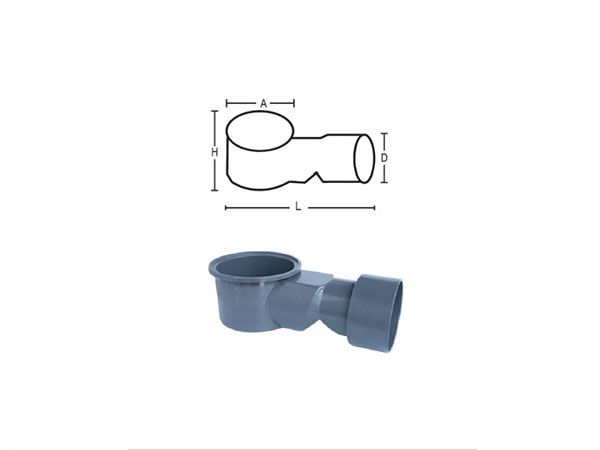

uPVC SWR Fittings

SAGAR uPVC SWR fittings are as per IS: 14735 specifications. They are available in selfit type which can be easily joined with SAGAR uPVC SWR sliding

socket end pipes and also with grooved socket end pipes with the help of uPVC SWR Ring Seal Adaptor.

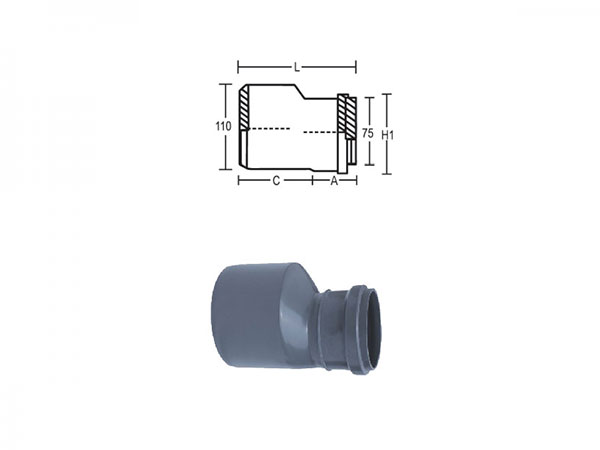

uPVC SWR Ring Seal Adaptor

SAGAR uPVC SWR Ring Seal Adaptor is specially designed to convert the sliding socket end joint to grooved socket end joint simply by snap fitting.

Rubber Ring

Sanitation lines are not concealed and are exposed to sunlight; hence there will be expansion and contraction due to temperature variations. Rubber rings

are used to accommodate these expansion and contraction. Rubber rings are available as per IS:5382.

Solvent Cement

SAGAR PVC solvent cement is to be applied for jointing sliding socket end pipes and fittings. It is also cost effective without affecting the performance.

Rubber Lubricant

SAGAR rubber lubricant is to be used to help easy insertion of uPVC pipes and fittings into rubber gasket. It also prevents growth of microorganisms like

bacteria, fungi etc.

Pipes should be stored on level ground with maximum up to 1.5 meter height. More weighted bundles should be stacked on the bottom. If the pipes are

stacked in rack, the spacing of the supports should not exceed 3 feet. Fittings should be stored in cartoons. Rubber rings should be kept tension free.

Rubber rings, solvent cement and rubber lubricant should be protected from direct exposure to sunlight and kept in proper ventilated area.

Reasonable care should be taken to handle the pipes and fittings. Throwing around or dragging or pushing or severe contact with sharp objects of pipes &

fittings should be avoided.

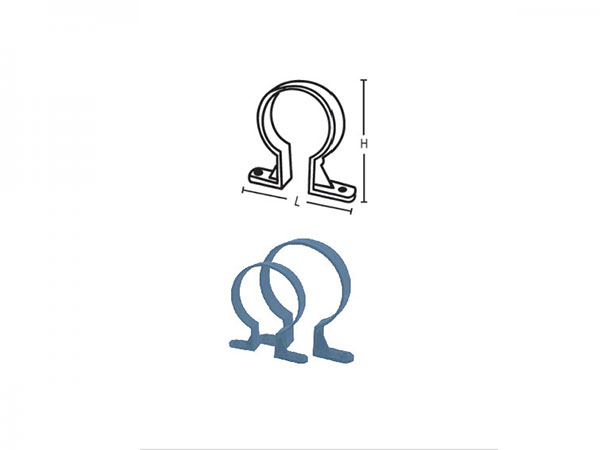

Support Spacing of Pipe Clips

For vertical lines, pipe clips should be spaced at intervals of 1 to 2 meters depending upon pipe diameter but for horizontal lines distance should not be

more than 10 times the outside diameter of the pipes.

Installation Methods

UNDERGROUND INSTALLATION

For underground installation, SAGAR uPVC SWR pipes should be laid in trenches. The trench width should be minimum pipe diameter plus 300 mm and

width should be 600 - 1000 mm, depending upon the pipe size and slope for gravity flow. Check the dirt is not entering from the joints and pipe lines are

not laid on submerged rock. Leakage testing is to be carried out before filling back the trench.

ABOVE GROUND INSTALLATION

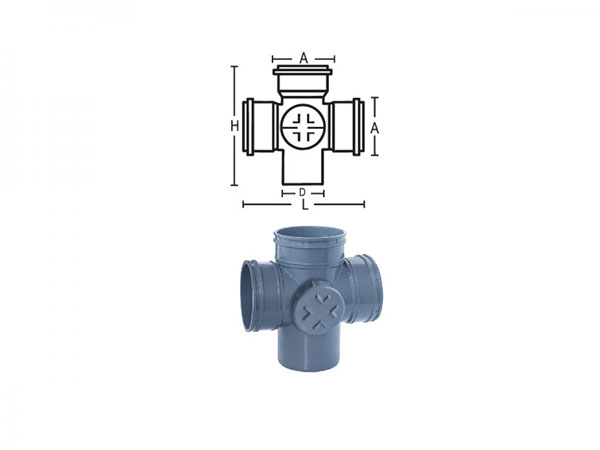

Use pipe clips as mentioned in the topic - support spacing of pipe clips. Cleansing pipe and fitting with door should be used at proper places to provide

access for inspection and cleaning.

CONCEALED INSTALLATION

For stress - free concealed installation of drain lines, slots should be made in the wall or concrete avoiding sharp edges. To prepare good base for proper

cement fixation while inserting SAGAR uPVC SWR pipes & fittings into the slots without a cement base, apply light coat of SAGAR PVC solvent cement,

then sprinkle medium sized dry sand. Leave till dry. In case of jointing PVC material to C. I. or A. C. material, these process is to be repeated. Before

concealing the system, leakage testing is to be carried out.

By using Y or Tee fittings and repair couplers, subsequent branch lines can be provided to existing SWR systems.

Testing Before Use

All openings below the top of the section to be tested should be sealed hermetically. Then water level is to be increased up to minimum 3 meters height

above the highest point of the section being tested or height is to be raised as per requirement. Every joint should be carefully examined for leaks.

Joining Technique

Solvent Cement Application For Sliding Socket End

Cut the pipe from plain end, make its end square

Using a chamfering tool or file, the end shall be chamfered to an angle of approximately 15°, to the axis of the pipe.

Remove burr, wipe the pipe end and fitting socket to remove all dirt, moisture and grease like lubricants by using clean rag.

Check dry fit of pipe and fitting and mark the distance length of pipe which goes into fitting socket.

Apply even and heavy coat of SAGAR PVC solvent cement on the external surface of the pipe and medium coat to the fitting socket.

Assemble the cemented parts quickly up to the mark by twisting pipe 1/8 to ¼ turn . To avoid push out, hold the assembly for about 60 seconds. A continuous bead of SAGAR PVC solvent cement is the evidence of proper joining.

Rubber Lubricant Application For Grooved Socket En

Cut the pipe from plain end, make its end square

Using a chamfering tool or file, the

end shall be chamfered to an angle of

approximately 15°, to the axis of the

pipe.

Remove burr and wipe the mating

surfaces to remove all dirt and

moisture

Apply SAGAR rubber lubricant on the

external mating surface and rubber

gasket.

Check the proper mounting position

of rubber ring and push the pipe into

socket. Mark the distance of pipe

depth in the socket.

Withdraw the pipe from the socket by

approx. 10 mm away to allow for

thermal expansion / contraction.

Converting The Sliding Socket End Joint To Grooved Socket End Joint

Solvent Cement Application For Sliding Socket End

Clean rib of sliding socket end fitting and internal surface of Ring Seal Adaptor.

Ring Seal Adaptor should be snap fitted firmly over the sliding socket end fitting with a uniform pressure.The click sound of snap fit is the evidence of perfect assembly. If required, the Ring Seal Adaptor can be detached by following same reverse procedure.

Joining Technique Insert the rubber ring into Ring Seal Adaptor.

Maintenance

MAJOR

If the damaged portion is above 300 mm, cut the pipe in total length of damaged portion plus two times diameter of the pipe. Use two repair couplers and

both side chamfered pipe in such a length of cutting. Slide one repair coupler to upper pipe and the other to lower pipe. Place the pipe in the gap and slide

both repair couplers over the juncture in opposite direction.

MINOR

Cut a piece of pipe having vertically unequal half cuts and bigger length than damaged portion. Apply light coat of SAGAR PVC solvent cement around

damaged portion and inside of half cut pipes and stick it over the damaged portion. Before use, dry them properly.

Disclaimer

Every care has been taken to provide the updated and correct information in this catalogue but it is not intended to form any part of any contract. No warranty is intended to be given or implied in respect of the contents thereof.

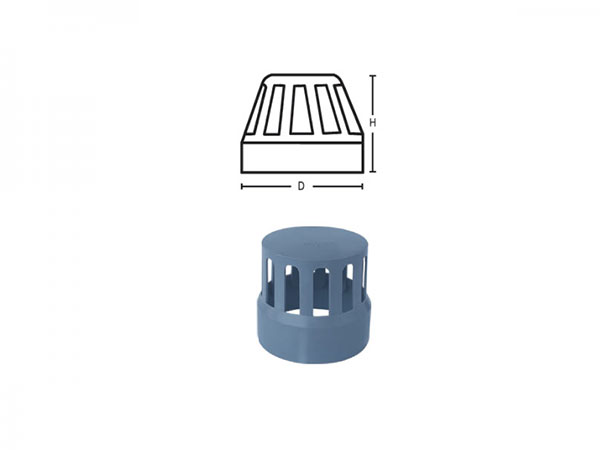

Types Of Sanitation System

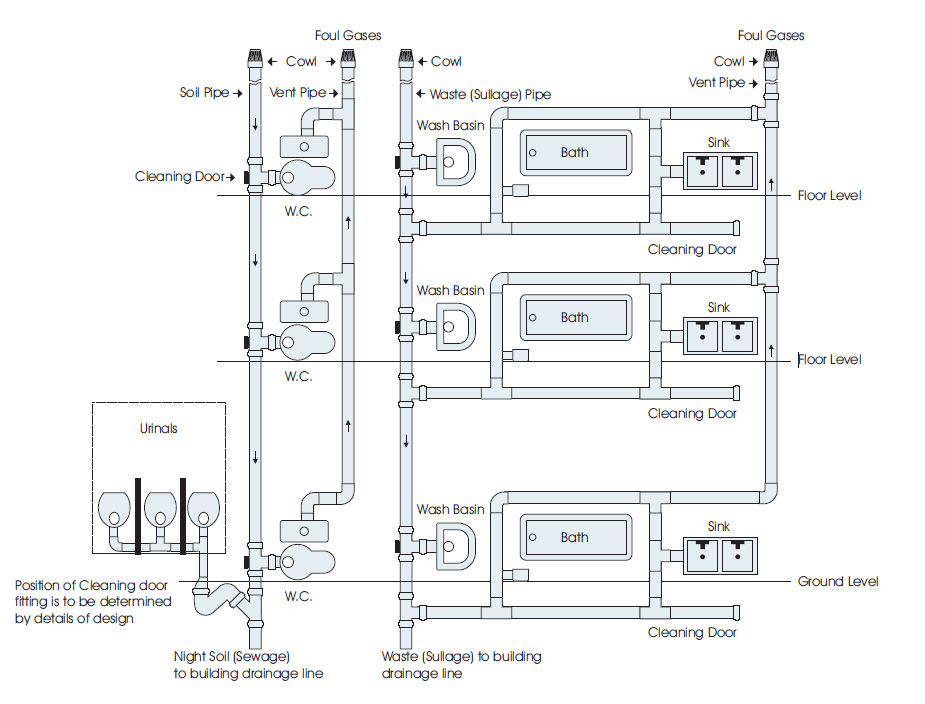

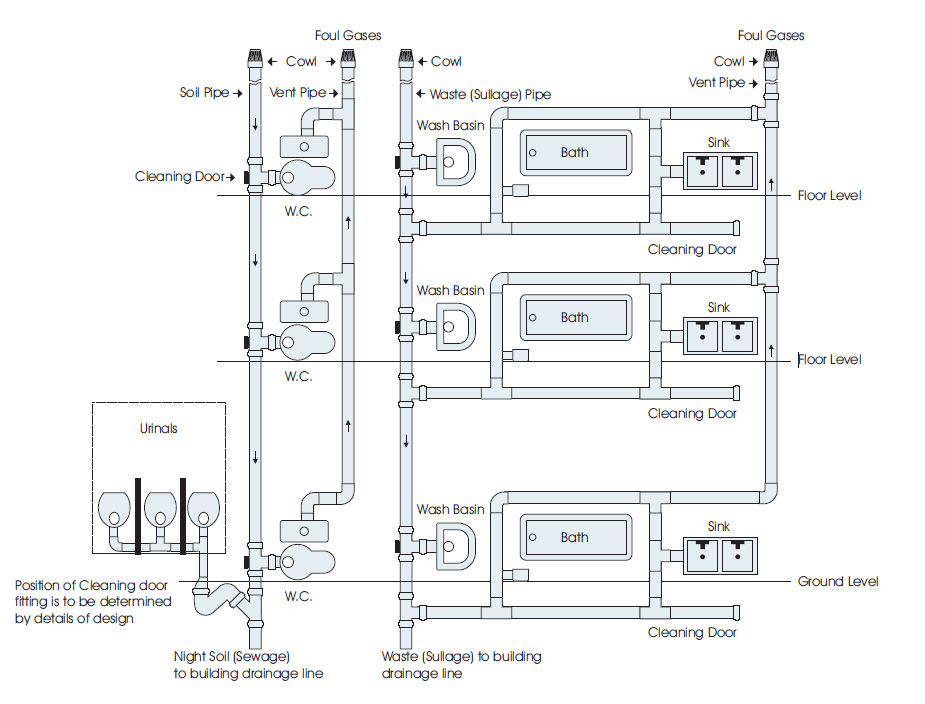

Two Pipes System

This is the best system and suitable for large housing schemes. Here, four different vertical pipelines in terms of two sets are to be laid, one is for draining waste matter and the other is for draining night soil. The silage fixtures such as baths, sinks and wash basins are all connected through the branch pipe to the vertical waste pipeline of 75 mm size and the soil fixtures such as latrines and urinals are all collected through the branch pipe to the vertical soil pipeline of 110 mm size. To prevent accumulation of foul gases, a separate vent pipeline is recommended to ventilate both these lines.

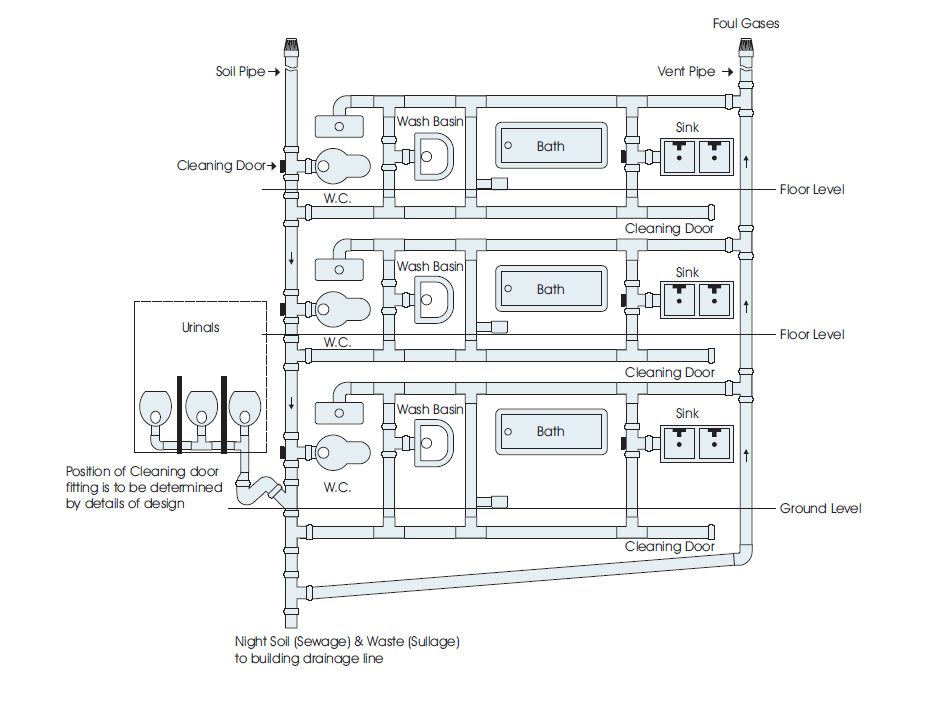

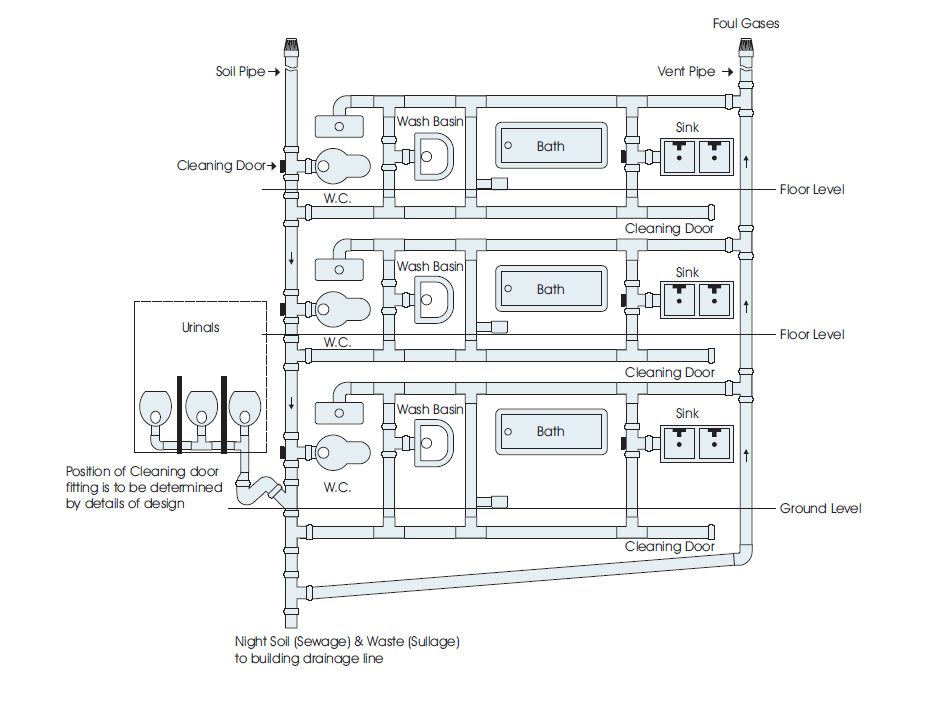

One Pipe System

This system is suitable for small housing schemes. Here, only one main vertical pipe line is to be laid which drains waste matter and night soil from the respective branches. Even though a vent cowl is provided on the top of the main line for ventilation, it is recommended to provide an additional vent line.

Read Less

Read Less